What is safety modification?

In the transformation process of project equipment, the understanding of engineers or maintenance engineers is different, and the equipment that has been transformed for many times may not meet the safety requirements, resulting in secondary risk injury Lihong safety engineering provides a professional safety team, including safety assessment team, on-site installation, transformation and installation team We have served in the safety transformation industry for 10 years and accumulated the safety transformation experience of all kinds of equipment From the most basic fence to the overall safety automation fixture and mold of complex mechanical structure robot, it can meet the requirements of enterprises in many aspects |  |

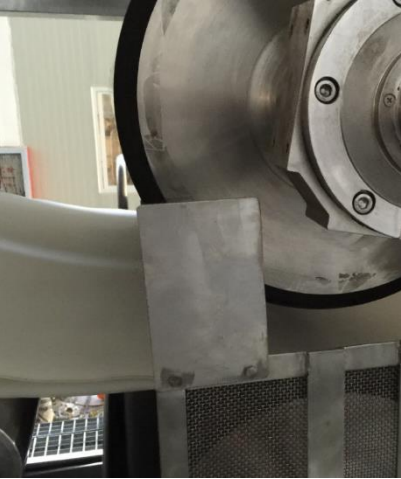

| In the safety transformation of all equipment, the design of mechanical safety occupies an important proportion Whether it conforms to the site installation and use, and if the design is unreasonable, it may lead to the direct removal of the operator Or the nonstandard mechanical design directly leads to the serious occurrence of secondary accidents |

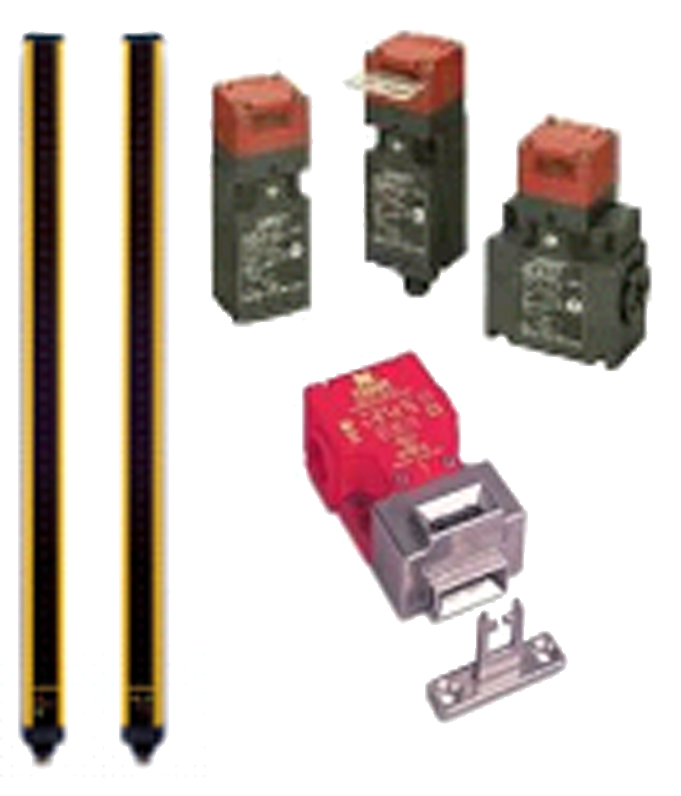

The importance of product selection

Many engineers or evaluators often neglect an important product selection, and some manufacturers may designate some manufacturers' brands. In fact, the selection of safety products should be combined with the actual application of on-site evaluation and the production site. According to the situation of the site, the equipment function, the right way to select the appropriate safety products is to choose the right one If the product selection is wrong, it may directly lead to unsuitable production or field application |  |

| Service selection | Service type | Order No |

| Installation design guide installation | Guide the safety design and installation of the enterprise team | AQFW |

| Installation and transformation | Overall safety design, installation and transformation | AQFW |

Safety engineering safety control system

The professional importance of the overall safety control system design of safety engineering:

Concept of safety control design

Safety controller / safety PLC has been more and more recognized by people, but in the process of using, there are still many users confused, why a set of similar PLC is named safety PLC, what are the differences between safety PLC and common PLC? We must distinguish the concept of safety design:

(1) Redundancy

(2) Different

(3) Self detection

| Performance level (PL for short) | GB/T 16855.1 性能等級 PL |

The ability of the relevant safety components of the control system to perform safety functions under the expected conditions is divided into five levels, which are called performance level (PL) Performance level refers to the discrete level used to specify the safety related components of the control system to perform safety functions under the expected conditions. | a |

| b | |

| c | |

| d | |

| e |

| PL is evaluated according to the structure of the control circuit of the safety function and the reliability of the constituent parts. The PL was evaluated by the mechanical manufacturer's device designer. The inherent mechanical safety reliability data of the control equipment shall be substituted into the structural elements (safety category and parameters such as CCF) and service conditions (parameters such as NOP and DCavg) of the safety related parts known only to the device designer for calculation. |

Components of safety control system

Machine control system components used to provide safety functions are called control system related safety components SRP / CS. They are composed of hardware and software, which can be independent of the machine control system, but also can be part of the machine control system. In addition to providing safety functions, SRP / CS can also provide operation functions (e.g. two hand start)

| input | control | output |

|  |  |

Automatic safety monitoring

Automatic monitoring

The diagnostic function of the fault response function is triggered if the ability of the element or component to perform its function is weakened, or the process condition changes to cause danger.

Direct opening action

Force disconnect operationposition opening operation

The specified action of switch operating parts directly realizes contact separation through non elastic parts (such as not relying on spring).

Prevent abandonment efeat in a reasonable foreseeable manner Discard safety devices by hand or through easily accessible objects. Use tools (screwdriver, wrench, hex key, pliers) that are required or easily available to remove the switch or operating parts. Enterprises that are often shielded Special anti disassembly fasteners are recommended for Lihong safety (special tools are required) |

|

|  |  |

Build a harmonious intelligent safety factory

Meet the upgrading requirements of intelligent security factory

After professional safety assessment

Plant equipment after professional safety transformation

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright ? Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing