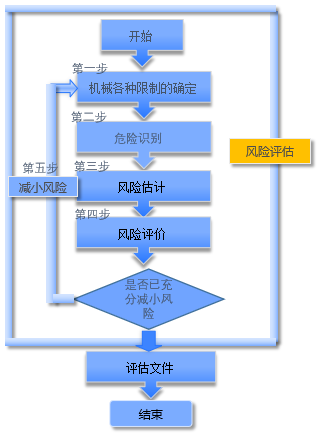

What is risk assessment and risk reduction

Procedures for identifying, estimating, and evaluating risks during the relevant phases of a machine's life cycle to eliminate or adequately reduce risks

| Step 1: machine qualification: Is to determine the scope of the system to be analyzed, such as the stage of the machine life cycle, the parts and / or functions of the machine. Step 2: hazard identification: The goal of hazard identification is to form a list of hazards, dangerous states and / or dangerous events, which can describe when and how dangerous states may cause injuries. Hazard identification is the most important step in any risk assessment. Only after the hazards are identified can actions be taken to reduce the risks related to them, and the unidentified hazards may cause injuries. Step 3: risk estimation After confirming the dangerous state and phenomenon of the machinery, determine the risk elements, and predict the danger through the "possibility of hazard occurrence" and "its probability" Step 4: risk assessment After the risk is estimated, the risk is evaluated to determine whether the risk needs to be reduced Step 5: risk reduction When the risk needs to be reduced, take the safety measures of design change and safety protection measures as shown in step 5. Repeat steps 1 through 5 to reduce the risk to an appropriate level |

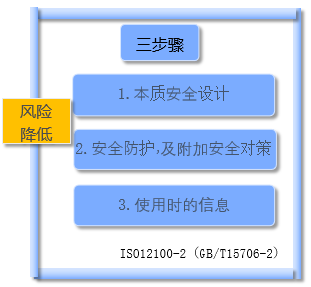

What is risk reduction

Risk reduction or reduction is to reduce the risk to an acceptable level by taking protective measures

Risk reduction is iso12100:2010 standard, which integrates iso12100-1:2003, iso12100-2:2003 and iso14121. This standard mainly provides the designer with the design steps and the basic conception of the whole mechanical safety including risk assessment.

| Step 1: intrinsic safety design measures Intrinsically safe design measures eliminate hazards or reduce associated risks by properly selecting the design characteristics of the machine and / or exposing the interaction of personnel with the machine. Intrinsically safe design measures are the first and most important step in the process of risk reduction Application of intrinsic safety design measures to control system The control system design measures shall be selected so that its safety related performance can reduce enough risks (see GB / T 16855.1 or IEC 62061). The correct design of the machine control system can avoid unexpected or potentially dangerous machine conditions. Step 2: safety protection and / or supplementary protection measures In consideration of the intended use and reasonably foreseeable misuse, if it is not feasible to eliminate the danger or fully reduce the risk related to it through the intrinsic safety design measures, the properly selected safety protection and supplementary protection measures can be used to reduce the risk Step 3: use information Although the intrinsic safety design measures, safety protection and supplementary protection measures are adopted, if the risks still exist, the remaining risks shall be identified in the use information. The information shall include but not limited to the following: ——The operation procedure of using the machinery shall meet the expected ability of the personnel using the machinery or other personnel exposed to the hazards related to the machinery; ——Describe in detail the recommended safe operation methods and relevant training requirements when using the machine; ——Sufficient information, including warnings of residual risks at different stages of the life cycle of the machine; |

Report professionalism

For the evaluated equipment, professional risk assessment report and risk point information shall be provided for inquiry and review

Since 2008, Lihong has independently designed the risk assessment software tool, which represents the professionalism and accuracy of the implementation of the standard in terms of the professionalism of assessment and the case accumulation of equipment

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright ? Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing